ISO 9001:2008 certified company was established in the year 2005

x

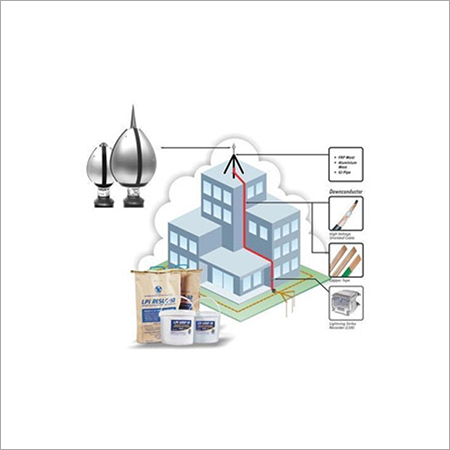

Conventional Lightning Protection System As per IEC62305

2000 INR/Unit

Product Details:

- Features High electrical conductivity, corrosion resistance, long service life, easy installation

- Pole Type Air Terminal Rod

- Thickness 10 mm to 25 mm (Rod Diameter)

- Usage & Applications Lightning protection for buildings, structures, and industrial facilities

- Mounting Type Roof-top mounting/Structure mounting

- Surface Finish Smooth/Polished/Corrosion-resistant coated

- Weight 2 kg to 8 kg (depending on length and material)

- Click to View more

X

Conventional Lightning Protection System As per IEC62305 Price And Quantity

- 1 Unit

- 2000 INR/Unit

Conventional Lightning Protection System As per IEC62305 Product Specifications

- Conventional rod system (Franklin rod)

- Copper/Metallic

- 1 Meter to 3 Meter (customized as per site requirement)

- High electrical conductivity, corrosion resistance, long service life, easy installation

- Up to 200 kA discharge capability

- 10 mm to 25 mm (Rod Diameter)

- Air Terminal Rod

- Lightning protection for buildings, structures, and industrial facilities

- 1 Meter to 3 Meter

- Roof-top mounting/Structure mounting

- Conventional Lightning Protection System

- Smooth/Polished/Corrosion-resistant coated

- -40C to +85C

- Up to 200 kA lightning current rating

- 2 kg to 8 kg (depending on length and material)

- High conductivity Copper or Aluminum

Conventional Lightning Protection System As per IEC62305 Trade Information

- 100 Unit Per Month

- 1 Days

Product Description

Conventional Lightning Protection System As per IEC62305 is an essential component of flat tape conventional lightning protection system. An air terminal or air termination network is designed to capture the lightning strike to a desired point, so that the discharge current can be safely and efficiently passed through the down conductors to the dedicated earthing system.Down Conductors:

The down conductor gives a low impedance path from the air termination to the earthing system, in order to safely conduct the lightning current to earth without the development of significantly large voltages. The route of down conductor must be direct to the earth and there must be no sharp bends or turns, so the risk of side flashing where impedance / inductance is accelerated under impulse conditions can be minimized.

Earthing System:

There must be a separate earthing system at each down conductor with a provision for the disconnection of each down conductor from the earthing system for the purpose of testing. Lightning protection system's resistance measured at any point must be less than 10 ohms, according to the International Standards. The potential rise of earth voltage can be minimized by boding together individual lighting earths, and these lighting earths must be bonded to surrounding facility earths.

Bonding to avoid Side flashing:

Lighting protection system must be bonded to all metal work in a building, for instance water pipes, gas pipes, AC units, metal roofs/ cladding, etc.

Design Concept:

The most common design method employed by lightning protection standards worldwide is the Rolling Sphere Method. It is based on the electro-geometric model which creates a link between peak current delivered by a lightning strike and striking distance. The rolling sphere method design involves rolling of an imaginary sphere of typically 45 metres over the structure to be protected. All structure points that are in contact with the sphere are the points that require protection, while the rest areas of the structure are regarded safeguarded.

Key Benefits:

- It is made in compliance to International Standards, like IEC 62305, Australian / New Zealand Standard AS/NZ 1768-2007 and British Standard BS EN 62305

- Wide range of conductors, connectors, air terminals, bases and fasteners

- It can be conveniently assembled and installed

- Lighting Protection Material: Copper-Clad Steel

Engineered for Robust Lightning Protection

Our system integrates high-conductivity copper or aluminum components for optimal performance, all conforming to the latest IEC 62305-3 standards. Each partair terminals, down conductors, clamps, and earth rodsis selected for its strength, corrosion resistance, and ease of installation. Applicable to a diverse range of buildings and lightning protection scenarios, the system is designed for both new constructions and retrofits, delivering safety and compliance.

Versatile Applications Across Sectors

Ideal for residential, commercial, industrial, and telecom infrastructure, our conventional lightning protection system provides reliable operation in various harsh environments. The components endure weather extremes from -40C to +85C, ensuring enduring performance on rooftops and structures of different sizes and designs. The customizable lengths and mounting options guarantee adaptability for every project.

Ease of Maintenance and Longevity

This lightning protection system is built for minimal maintenance, with periodic inspections being the only recommended care. Corrosion-resistant coatings and polished finishes extend its service life even in challenging outdoor settings. Comprehensive accessories such as base plates, clamps, and connectors simplify upkeep and integration with existing infrastructure.

FAQs of Conventional Lightning Protection System As per IEC62305:

Q: How is a conventional lightning protection system installed on buildings?

A: Installation involves mounting the air terminal rods on rooftops or structures, connecting down conductors made from high conductivity copper or aluminum strips, and securely fixing earth rods into the ground. Components are linked using clamps and base plates, ensuring the whole system directs lightning safely into the earth.Q: What standards does this lightning protection system comply with?

A: Our system is designed and manufactured in strict accordance with IEC 62305-3:2010 and IS/IEC 62305-1 to 4 standards, meeting international and Indian regulatory requirements for lightning protection.Q: When should periodic inspections of the system be performed?

A: Periodic inspections are recommended annually or after severe weather events to ensure all componentsair terminals, conductors, clamps, and earth rodsremain secure, undamaged, and electrically continuous.Q: Where can this lightning protection system be used effectively?

A: The system is suitable for residential homes, commercial complexes, industrial plants, telecom towers, and structures requiring protection from direct lightning strikes and surges.Q: What is the process for customizing the system for different site requirements?

A: Length, material, and type of components such as rods and conductors can be tailored according to site-specific needs. Our team assesses the structure, recommends suitable configurations, and provides customized components for effective protection.Q: How does this system benefit property owners and facility managers?

A: By safely channeling lightning energy away from buildings, the system prevents structural damage, equipment loss, and potential fire hazards. Its low maintenance and long service life result in reduced operational costs and enhanced asset protection.Q: What are the main features that ensure long-term reliability of this lightning protection system?

A: Key features include high electrical conductivity, superior corrosion resistance, smooth or coated finishes, robust construction, and compatibility with a variety of accessories, all contributing to dependable and long-lasting lightning protection.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Lightning Protection (ESE & CSE)' category

|

ALLIED POWER SOLUTIONS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese